Flexbot design: Difference between revisions

No edit summary |

No edit summary |

||

| Line 20: | Line 20: | ||

[[File: | [[File:Teensy Wheel Configuration.png|1050px]] | ||

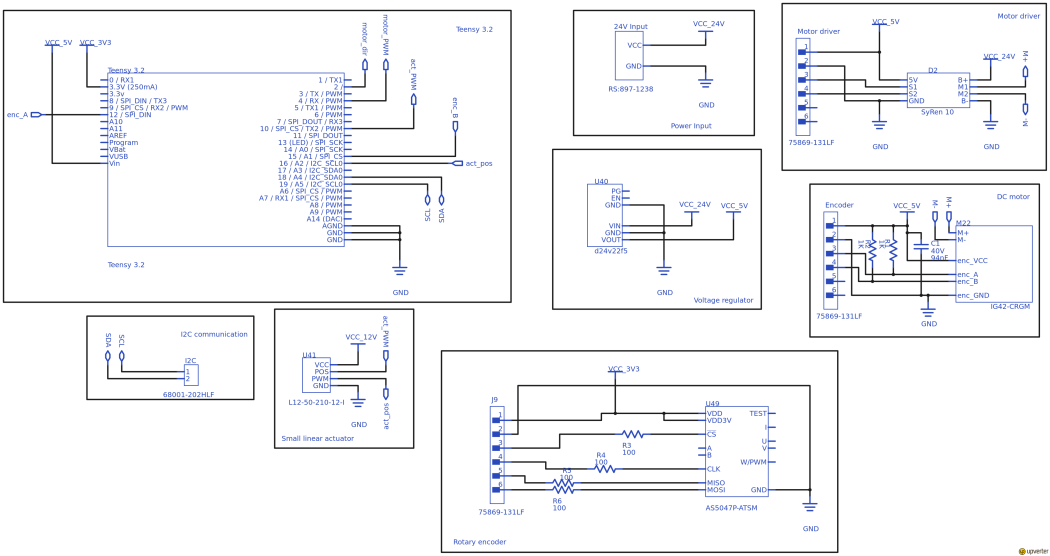

Figure 1: Schematic for the ankle configuration for the Flexbot. | Figure 1: Schematic for the ankle configuration for the Flexbot. | ||

Revision as of 08:31, 11 July 2017

Back to Flexbot main page

Design overview hardware

Each "leg" of the flexbot consists of 4 actuators.

- An angled DC motor to control the wheel.

- Two linear actuators to control the motion of the robot's body.

- A linear actuator to adjust heading angle on the wheel.

Each of the legs are interfaced and controlled by two μ-processor boards (Teensy 3.2 and 3.5). The boards are currently placed on matrix boards where other hardware components (IMU, motor driver, etc.) are accessible from. Each leg is split up in two parts which are presented as the ankle configuration and the knee configuration. The hardware design for robot's body is presented here.

Ankle hardware design

The ankle configuration currently includes:

- Angled DC motor to run the wheel - model IG42-CRGM

- SyRen 10 motor driver

- Teensy 3.2 μ-processor board

- Pololu 24V to 5V voltage regulator - model D24V22F5

- Firgelli L12-50-210-12-I linear actuator

The schematic for the ankle configuration is shown in Figure 1 and can be accessed using the free online e-CAD design tool Upverter. Link to the project on Upverter is given here.

Figure 1: Schematic for the ankle configuration for the Flexbot.

Knee hardware design

The knee configuration currently includes:

- A linear actuator to control the height (tilt) of the configuration - model DLA-12-10-A-200-POT-IP66

- Cytron 10A DC Motor Driver - model RB-Cyt-132

- MPU to obtain tilt - model MPU-9250/6500

- Teensy 3.5 μ-processor board

The schematic for the knee configuration is shown in Figure 2 and can be accessed using the free online e-CAD design tool Upverter. Link to the project on Upverter is given here.

Figure 2: Schematic for the knee configuration for the Flexbot.