Inspection robot: Difference between revisions

| Line 11: | Line 11: | ||

Green towards motor | Green towards motor | ||

yellow center | yellow center | ||

Red away from motor | Red away from motor. | ||

- or maybe more likely, motor is turned 180 deg. | |||

* Power: | * Power: | ||

Revision as of 13:46, 25 September 2014

Installation and use noted for 6-legged inspection robot.

Servo with feedback

The servo software is build upon the "Open servo" project, with a slightly modified PCB.

Hardware

- Potentiometer mount:

Green towards motor yellow center Red away from motor.

- or maybe more likely, motor is turned 180 deg.

- Power:

At least 6.5V - to allow regulator to give 5V

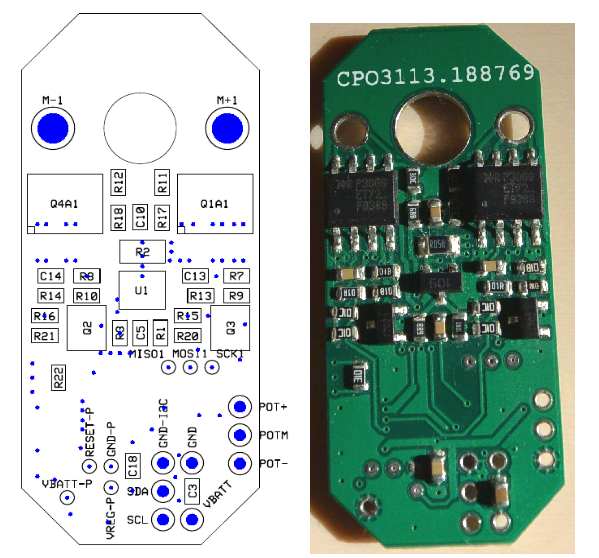

- Layout of servo-print with connections. Looks like Vbatt-P is connected to pot-, this can not be right?

Software

P value must be set to (about 50) to make servo run. This gives some overshoot for large steps. A D-value makes it worse.

Need to investigate control-part of servo.

Update rate seems to be slow (~10Hz) investigate.

EMF sense is not in software

Current has some reaction, but no reaction to load? - investigate.

RHD plugin

A new plugin is uploaded using USBISS converter to i2c - should be changed to i2c on target platform

Setting and main status for N servos (up to 24) implemented. Debug status for 1 servo implemented (first 48 registers are monitored)

Commands (write with register adress above 0x7f) is working

0x82 (130) enable PWM 0x83 (131) disable PWM etc - see main.c in software

Change of i2c address is not implemented/tested (there is a save to eeprom command)