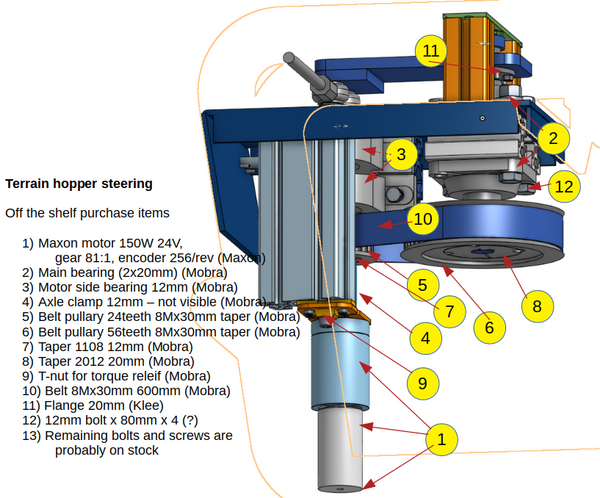

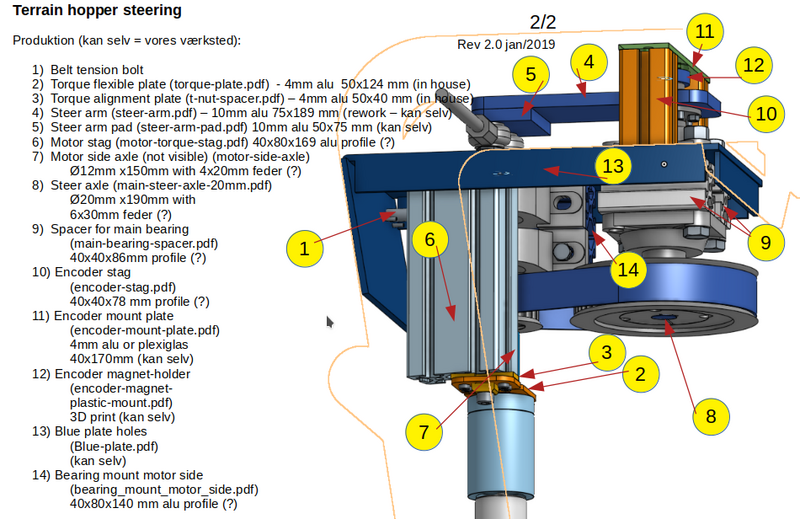

Terrain hopper steering

Back to TerrainHopper

CAD drawings

Overview of new steering proposal

Figure 1. New steering part maintaining original steering axle position, but replacing with bearings and a belt drive to a maxon gear motor. This figure points to most of the off-the-shelf parts used.

See purchase detail in Terrain-hopper binder (Christian office - red binder).

Figure 2. New steering part maintaining original steering axle position, but replacing with bearings and a belt drive to a maxon gear motor. This figure points to most of the parts that needs workshop assistance. Most of the parts - except axlesl (7 and 8) - can be manufactored on own workshop. The axles will be manufactored by axle supplier.

Maxon motor

The motor for steering is a Gear-motor-encoder combination from Maxon:

GEAR Planetary Gearhead GP 52 C Ø52 mm, 4 - 30 Nm, Ceramic Version Outer diameter: 52 mm Reduction: 81 : 1 Max. continuous torque: 30 Nm Part No.: 223093 (345€)

MOTOR RE 40 Ø40 mm, Graphite Brushes, 150 Watt Part No.: 148867 (347€) Outer diameter: 40 mm Type power: 150 W Nominal voltage: 24 V No load speed: 7580 rpm Nominal torque (max. continuous torque): 177mNm

SENSOR Encoder MR, Type L, 256 CPT, 3 Channels, with Line Driver (5V) Counts per turn: 256 Number of channels: 3 Line Driver: Yes Part No.: 225783 (93€)

Sensor has 10 pins, but cable is a 8 pole network cable, cable colors and (pin number (rj45 end))

1 NC 2 VCC - blue/white (5) 3 GND - blue (4) 4 nc 5 Ainv - orance/white (1) 6 A - orange (2) 7 Binv - green/white (3) 8 B - green (6) 9 Iinv - brown/white (7) 10 I - brown (8)

The Maxon encoder sensor is not used (march 2019)