Regbot encoder analysis

Regbot encoder issues

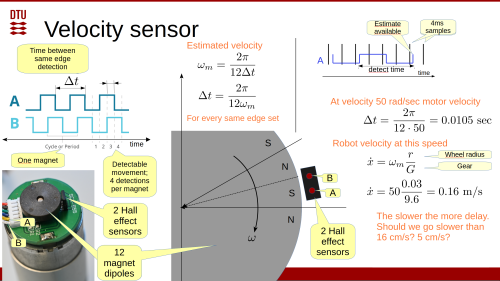

The Regbot motors use a magnetic encoder at the motor axle, as shown below.

The encoder has 12 magnets and two HAL sensors. The sensors have a separation and position that should give symmetric A and B signals, as shown. If all magnet dipoles have exactly the same size and strength, then velocity can be estimated using the time between any two flanks. But this is not the reality.

A more stable velocity is obtained using the time between the same flank on the same signal, e.g. the rising flank on the A signal. This gives a velocity estimate at every flank, but the velocity is estimated over a longer time.

The average delay is half the time between two equal flanks on the same signal plus the time since the flank was detected.

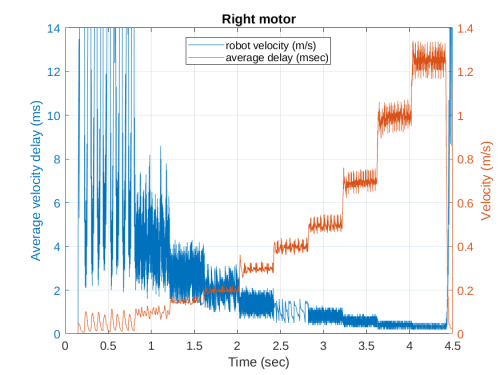

The following plot tests this. A fast PI velocity controller is used to obtain stable velocities between 0.05 and 1.3 m/s. The motor gear is 9.6:1, and the wheel radius is 0.03m.

The magnetic encoder is used to calculate motor (and robot) velocity, which is estimated based on the time between encoder ticks.

At a robot velocity of 5 cm/sec, the average delay is often more than 30 ms. The velocity controller is not well designed for this delay.

The velocity is more stable at 10 cm/sec, and the average delay is less than 10 ms.

At 0.5 m/sec and faster, a repeating pattern is visible. This pattern is related to the velocity and is repeated for every motor rotation. This indicates that the magnets in the encoder are not equal or symmetric. In this case, the resulting velocity noise is about 10% of the velocity.