|

|

| (157 intermediate revisions by 2 users not shown) |

| Line 1: |

Line 1: |

| Small robot intended for control-1 exercises.

| |

|

| |

|

| [[File:regbot-final.png|200px]] | | REGBOT is a small robot designed for exercises for our linear control 1 course (PID control) ([http://www.dtu.dk/english/Service/Phonebook/Person?id=14453 author]). |

|

| |

|

| ==Hardware status==

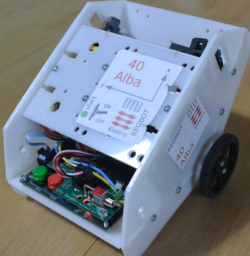

| | [[file:foto_of_Alba_40.png | 250px]] |

|

| |

|

| REGBOT comes in 2 versions:

| | Figur 1. Version 2 of Regbot. |

| * version 2A - with robot number 1..15

| |

| * version 2B - with robot number 16..36

| |

| [[REGBOT robot status]]

| |

|

| |

|

| ==Software download== | | == Overview == |

|

| |

|

| *Robot software (regbot.hex): 2.124

| | This section is intended for users. |

|

| |

|

| *Client software for windows (regbot.exe): 2.124

| | [[Getting started]] with REGBOT GUI. |

|

| |

|

| (as of September, 2015)

| | [[User interface]], how to configure the robot using the Regbot client. |

|

| |

|

| repository for software - client and robot

| | [[Control]] overview gives some information on control possibilities. |

|

| |

|

| * client: svn://repos.gbar.dtu.dk/jcan/regbot/qtgui

| | [[Mission]], how to write a mission. |

| * robot: svn://repos.gbar.dtu.dk/jcan/regbot/regbot

| |

|

| |

|

| On a Linux computer do something like this:

| | [[Regbot calibration]] for better performance. |

| svn co svn://repos.gbar.dtu.dk/jcan/regbot/regbot .

| |

| svn co svn://repos.gbar.dtu.dk/jcan/regbot/qtgui .

| |

|

| |

|

| ==Install software==

| | [[Regbot maintenance]] for longer life. |

|

| |

|

| Get the regbot.exe from the course homepage, place it in a directory, this directory will be default for configuration file and result files from the robot.

| | [[Regbot GUI]] installation. |

|

| |

|

| A driver must be installed to get in contact with the robot - see [[installation in windows]]

| | [[Regbot hardware board]]. |

|

| |

|

| The driver will create a com-port when connected - most likely com3 or any higher number.

| | == Install notes == |

| When the robot is disconnected by unplugging the cable, then the client needs to be restarted if it was connected when the cable was unplugged (no connection detect in windows).

| |

|

| |

|

| * [[Software installation]] and tool-chain - Linux

| | This section is primarily installation notes and more detailed descriptions not usually needed by the end-user. |

| * [[installation in windows]] some of the tool-chain

| |

| * [[Schematic]]

| |

|

| |

|

| | [[Regbot command interface]] - command list. |

|

| |

|

| ==User interface==

| | [[Software installation]] on REGBOT (Arduino) and tool-chain - Linux |

|

| |

|

| The user interface can configure and run the robot, as well as inspecting almost all values on the robot. Written in python using Qt GUI library.

| | [[Regbot old stuff]] |

| | |

| [[File:Gui_rev0.png]] | |

| | |

| The GUI allows to make step responses for velocity and turn. The step response is recorded in a buffer on the robot and is fetched in a MATLAB style file (as shown).

| |

| Interface points that are recorded can be switched on and off to better utilize the limited buffer size on the robot (35kBytes).

| |

| | |

| [[File:Gui_ctrl_rev_1.png]]

| |

| | |

| This is a page to make a step response and insert controller values for velocity control. The same controller is used for both wheels.

| |

| | |

| ==Design overview hardware==

| |

| | |

| [[File:blockdiagram_rev2.png]]

| |

| | |

| Hardware blockdiagram.

| |

| Most blocks are off-the-shelf hardware modules from PJRC (Teensy), Pololu (motor, driver and buck-boost converter) and Sparkfun (IMU).

| |

| | |

| A line sensor is planned, but not implemented yet.

| |

| | |

| ==Design overview software==

| |

| | |

| [[File:blockdiagram_software.png|900px]]

| |

| | |

| Overview of software data flow. Yellow is control blocks.

| |

| Green is hardware (motor and sensor), Light green is calculations. Light blue is obtained values.

| |

| Gray is input values.

| |

| | |

| Sample time for all controllers and data values are 1ms.

| |

| All software is written in c++, based on Arduino libraries.

| |

| | |

| | |

| * [[Design calculations]]

| |

| | |

| ==PCB connections revision 2B==

| |

| | |

| Component placement and values (in red) are shown here.

| |

| Plug connections are shown in blue.

| |

| | |

| [[File:component-drawing.png]]

| |

| | |

| The Sharp IR sensor output is not connected to an AD converter input.

| |

| | |

| The IR sensor voltage divider output should be between 0 and 1.2V,

| |

| and could be connected to A8 and A9 (used to be feedback from motor-controller).

| |

| Unfortunately a plug can not be mounted (space conflict with USB plug).

| |

| | |

| The orange wire is a patch (line sensor low power).

| |

| | |

| ==Install hardware - version 2A==

| |

| | |

| The motor and IMU wires are mounted as shown here.

| |

| The IMU uses 4 wires only, so only the rightmost pins (1..4) on the main board are used.

| |

| | |

| [[File:motor-imu-wire.png]]

| |

| | |

| Pin 1 on the IMU is as shown here

| |

| | |

| [[File:imu-wire.png]]

| |

| | |

| The teensy processor and power is connected as shown

| |

| | |

| [[File:teensy-annotated.png]]

| |