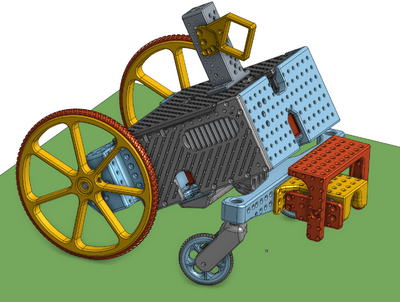

Robobot hardware

From Rsewiki

Back to Robobot B

Hardware

Mounting holes

The hardware is 3D-printed plastic (except for the electronics and screws)

All 3D printed parts have holes for mounting additional parts. These holes have:

- Individual hole distance of 1cm.

- Hole diameter of 2.5mm, intended for 3mm plastic screws.

- Plastic thickness is 6mm in most cases.

Screws for plastic (PT screws)

Mounting items on the 3D-printed thermoplastic should use plastic (PT) screws.

Plastic (PT) screws:

- Cut into the plastic with a sharp high-pitch thread.

- Gets locked into the plastic.

Plastic (PT) screw selection:

- Pan-head 2.5mm for PCB mounting, length 8mm, Torx 8IP/TX8.

- Countersunk 3mm length 10mm, TX8, for the most plastic-plastic mount, where head height is important.

- Pan head 3mm, length 10mm, TX10, for the most plastic-plastic mount, with space for the head.

- Pan head 3mm, length 16mm, TX10, for servo arm 'axle'.

- Countersunk 3mm, length 25mm, TX8, box lit 'bearing' and camera mount.

- 6mm, 10, 14mm, 18mm

- Countersunk 3mm

- 10mm, 14mm

Pan head screw for thermoplastic.

Screws for metal

Mounting of motors and other metal parts should use screws for metal.

Metal screw selection:

- M3 pan head (servo horn 16mm, Torx TX10)

- M3 countersunk (motor mount 12mm, Torx TX10)

- M5 bolt (For the main wheel fastner, 16mm, Hex/Umbraco 4mm)

- M5 nut (For the main wheel fasten).

- M6 bolt (Castor axles, length 50mm, Hex/Umbraco 5mm)

Screw drive type

We could, unfortunately, not standardize on one type of screw drive type.

Drive types used:

- Umbraco (Allan) type: plane hexagonal drive and tool (mostly 3, 4 and 5mm)

- Cross PH (Philips type) is not used much (size PH0, PH1, PH2).

- Cross PZ (Pozidrive) is not used much (size PZ0, PZ1, PZ2).

- 6-lobe or (Tork) (size T08 and T10 are used)