Robobot circuits: Difference between revisions

| Line 37: | Line 37: | ||

[[File:PCB_foto_8.5.jpg | 900px]] | [[File:PCB_foto_8.5.jpg | 900px]] | ||

Figure 5. Populated PCB. | Figure 5. Populated PCB with Teensy 4.1 and O-LED display. | ||

[[File:PCB_foto_8.5_annotated.jpg | 900px]] | [[File:PCB_foto_8.5_annotated.jpg | 900px]] | ||

Revision as of 17:30, 27 December 2024

Back to Robobot_B

Digital IO

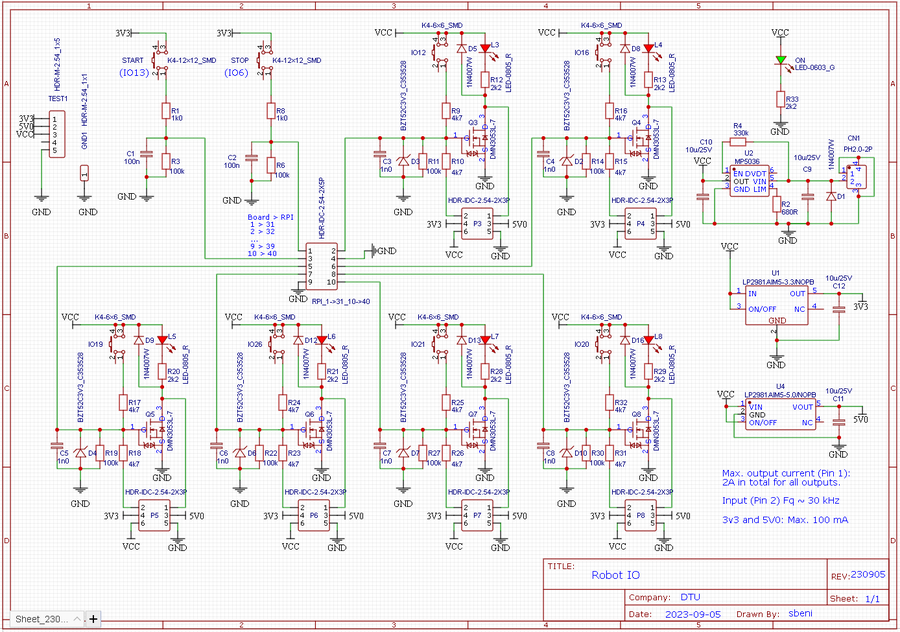

Circuit diagram

Figure 1. The circuit diagram should ensure that each IO pin can function as both input and output. If input, then the pin has active pull down, i.e. for input to change, it must be pulled high, to at least 3.3V, but 5 or 12V will work too. If output, then a transistor is active when output is high, and can draw at least 1A from the 12V supply. The 5V and 3.3V can supply no more than 100mA.

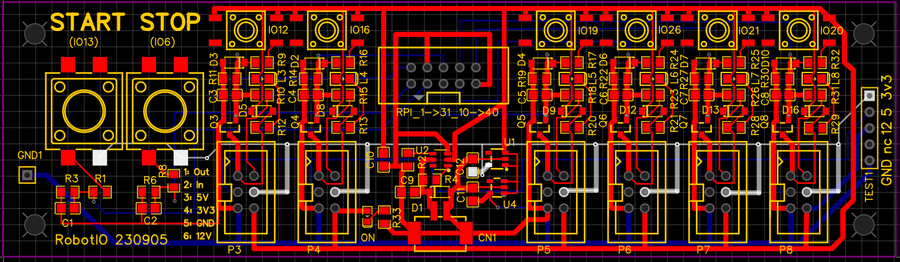

PCB

Figure 2. The PCB layout for the digital IO circuit.

Regbot

Circuit diagram

Figure 3. The Robobot circuit for version 8.5 (circuit is the same as version 8.4).

PCB

Figure 4. PCB with more trace details.

PCB - 3D view

Figure 5. Populated PCB with Teensy 4.1 and O-LED display.

Figure 6. Connectors. Unused connectors are: 2 I2C plugs (I2C and I2C1), SPI plug (with driver for AS5147), ON-OUT that can be used to power on other similar boards (connect to on-in).

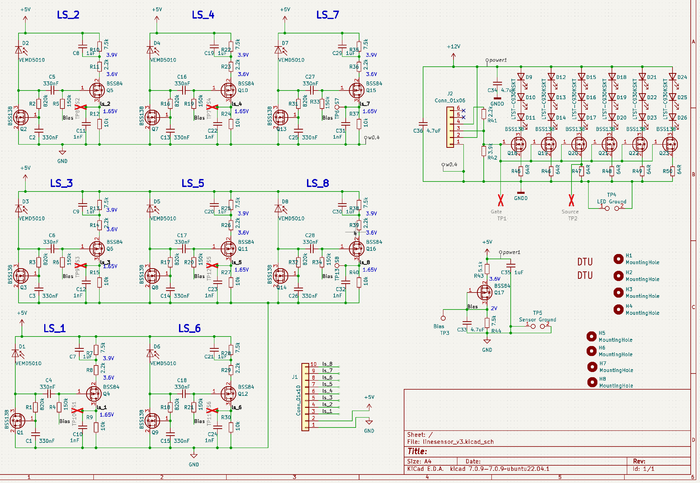

Line sensor

Circuit

Figure 6. Circuit diagram for the line sensor. 8 sensors with a change amplifier and analogue output. The 18 LEDs provide the blinking light at the sample rate (on Regbot 1kHz).

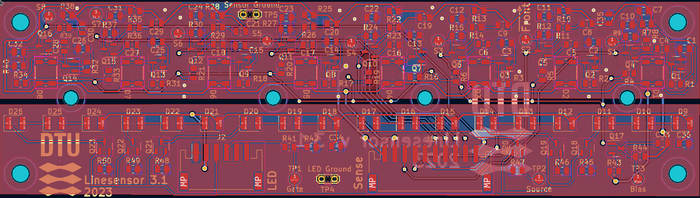

PCB

Figure 7. The PCB in 3D view. The distance from the first to the last sensor is 12cm.

Figure 8. PCB layout.

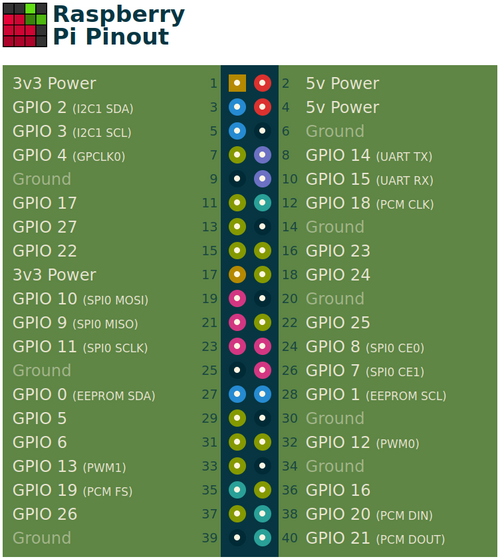

Raspberry PI

Figure 9. GPIO pin numbers, the bottom 10 pins are used for the IO-board. Pin1 on the cable match Pi pin 31 (GPIO6).