Robobot circuits: Difference between revisions

No edit summary |

|||

| Line 38: | Line 38: | ||

Figure 5. PCB with more trace details. | Figure 5. PCB with more trace details. | ||

== Line sensor == | |||

[[File:line_sensor_3.1_circuit.png | 700px]] | |||

Figure 6. Circuit diagram for the line sensor. 8 sensors with a change amplifier and analog output. The 18 LEDs provides the blinking light (1kHz). | |||

[[File:line_sensor_3.1_PCB_3D.png]] | |||

Figure 7. The PCB in 3D view. | |||

[[File:line_sensor_3.1_PCB.png]] | |||

Figure 8. PCB layout. | |||

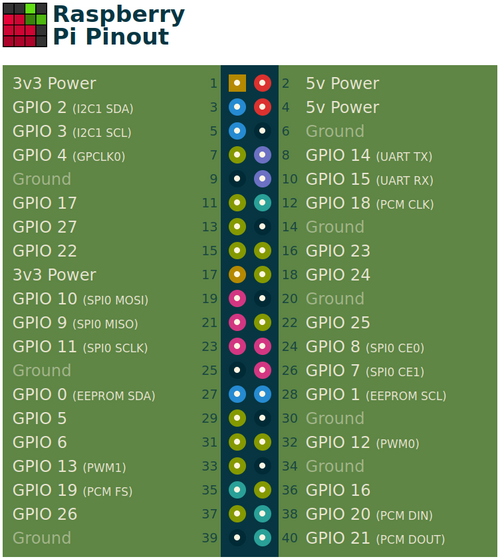

== Raspberry PI == | == Raspberry PI == | ||

| Line 43: | Line 58: | ||

[[File:Raspberry_Pi_GPIO_pins.png | 500px]] | [[File:Raspberry_Pi_GPIO_pins.png | 500px]] | ||

Figure | Figure 9. GPIO pin numbers. | ||

Revision as of 10:58, 28 December 2023

Back to Robobot_B

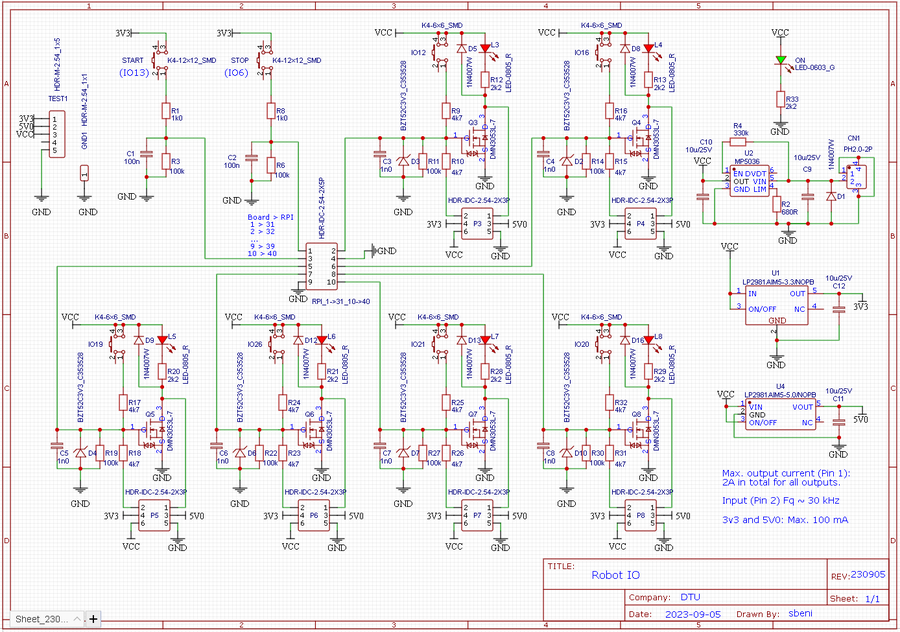

Digital IO

Circuit diagram

Figure 1. The circuit diagram should ensure that each IO pin can function as both input and output. If input, then the pin has active pull down, i.e. for input to change, it must be pulled high, to at least 3.3V, but 5 or 12V will work too. If output, then a transistor is active when output is high, and can draw at least 1A from the 12V supply. The 5V and 3.3V can supply no more than 100mA.

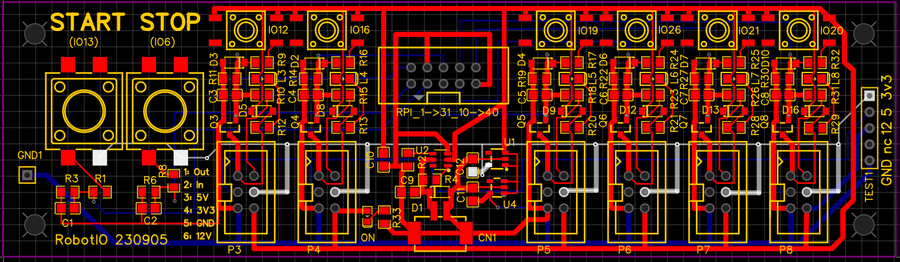

PCB

Figure 2. The PCB layout for the digital IO circuit.

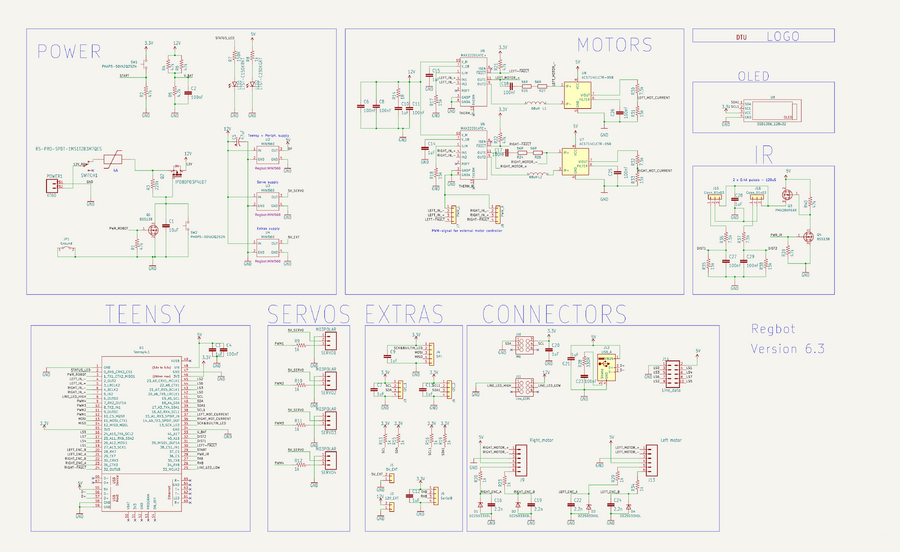

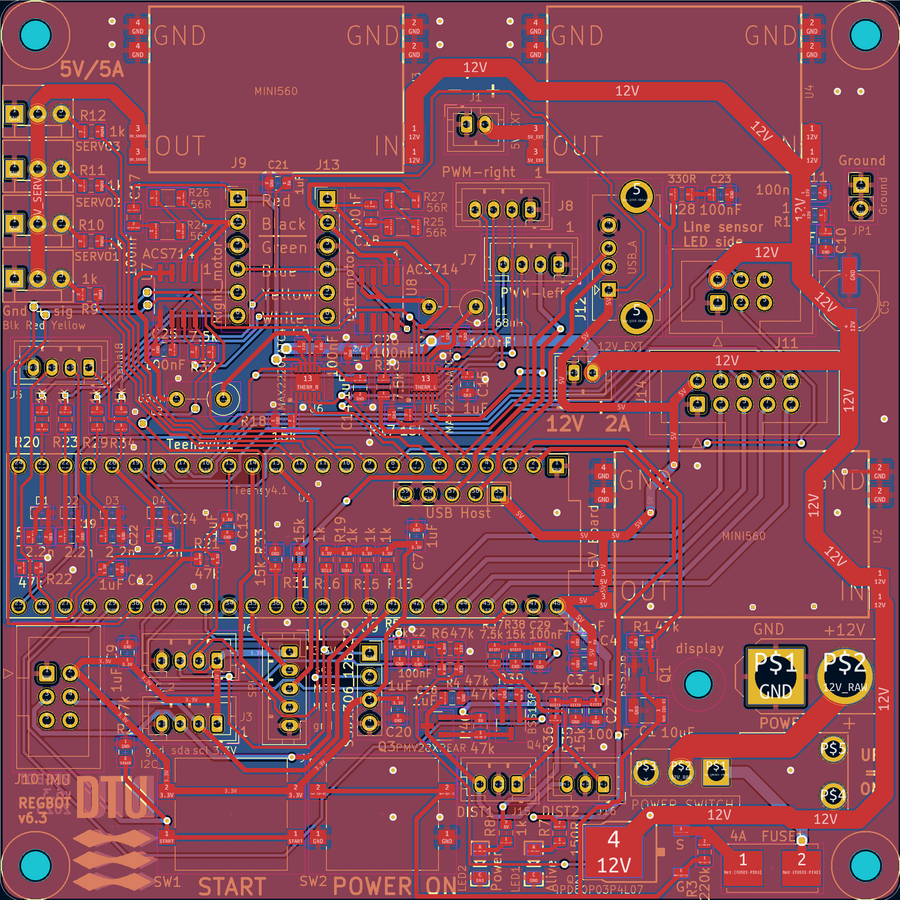

Regbot

Circuit diagram

Figure 3. The Regbot circuit.

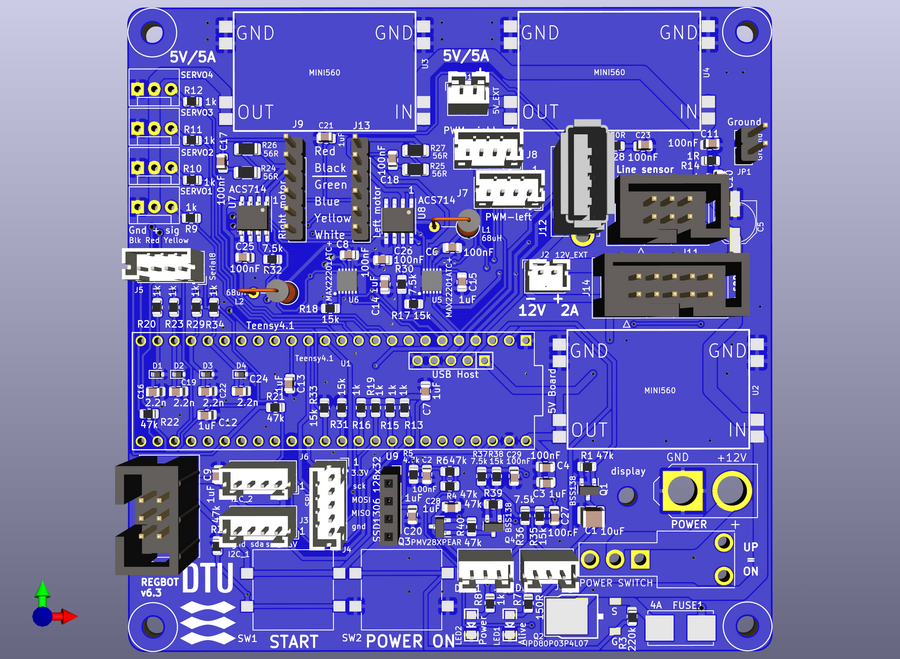

PCB - 3D view

PCB

Figure 4. Ecpected view of PCB.

Figure 5. PCB with more trace details.

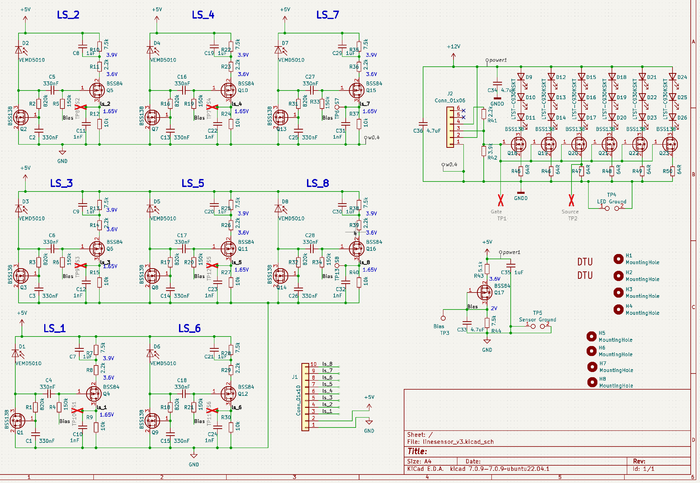

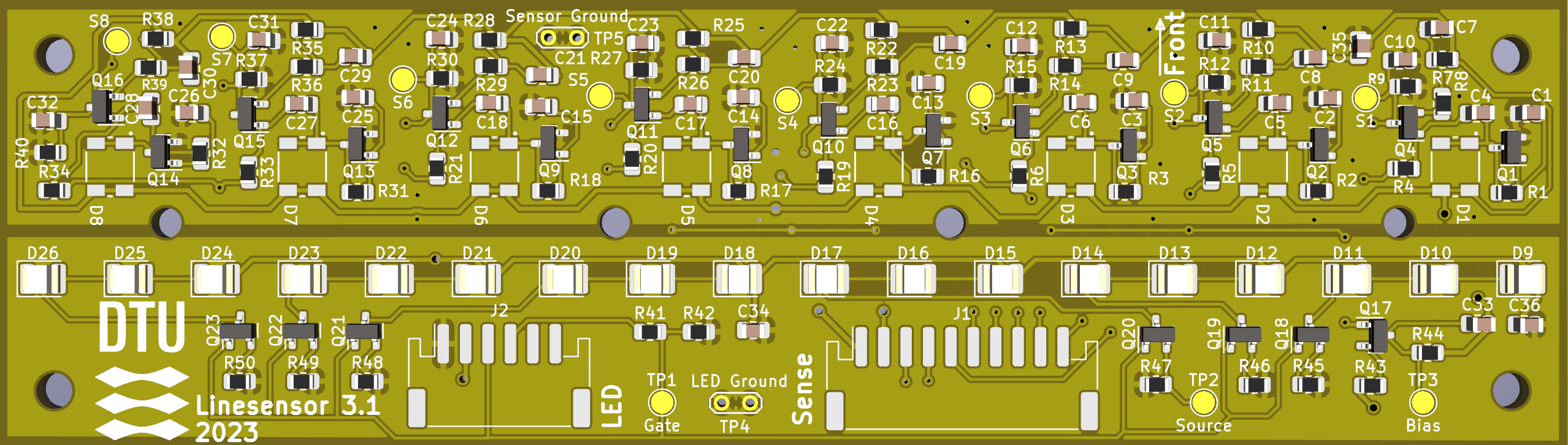

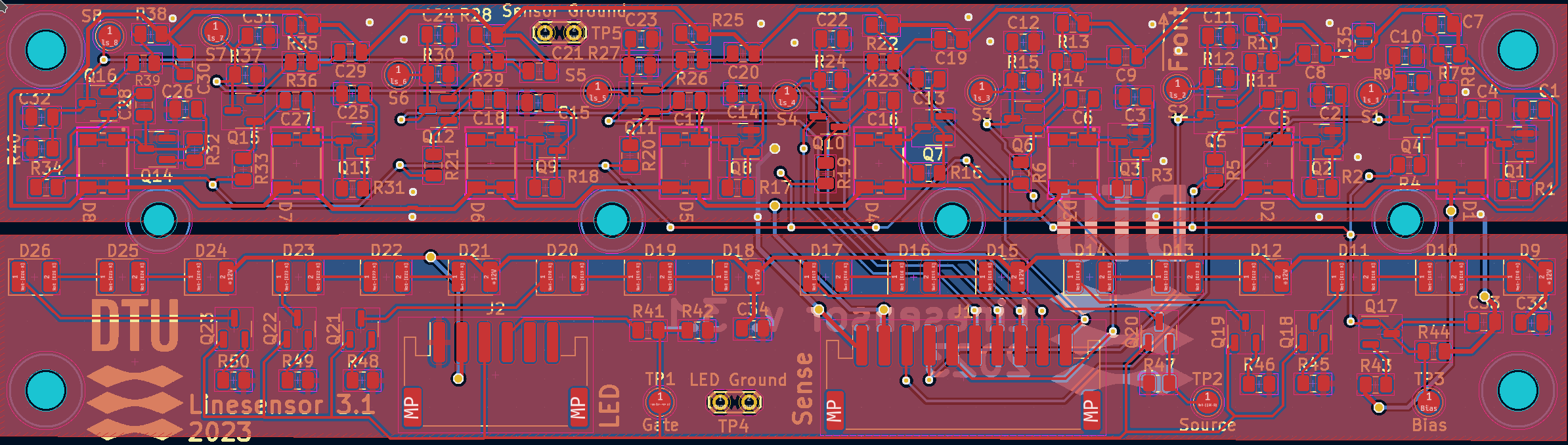

Line sensor

Figure 6. Circuit diagram for the line sensor. 8 sensors with a change amplifier and analog output. The 18 LEDs provides the blinking light (1kHz).

Figure 7. The PCB in 3D view.

Figure 8. PCB layout.

Raspberry PI

Figure 9. GPIO pin numbers.